Opening up High

Performance Computing to the Discrete Element Method User Community

G.Marketos, Civil and Environmental Engineering Department,

Imperial College London

Abstract

Discrete

element modelling (DEM) is used to simulate the response of granular materials

for civil, process or chemical engineering applications. It is also used by

physicists, geologists, geophysicists and mathematicians. The DEM algorithm is similar to molecular dynamics (MD) in many ways, but

take up of high-performance computing (HPC) by the DEM user community is

very low in comparison to the use of HPC for MD applications. Consequently the

impact of current DEM simulations on industry and in basic science is restricted.

The Large-scale Atomic/Molecular Massively Parallel Simulator LAMMPS is a widely used MD simulator.

Due to the algorithmic similarities between DEM and MD, LAMMPS is a very good

platform for DEM simulations. LAMMPS had previously included a “granular”

module for DEM simulations, and while the resultant code is highly scalable, it

lacks the necessary functionality for the majority of DEM applications.

The main objective of this

project was to add key functionality to granular LAMMPS by implementing new C++

code. This has increased significantly the type and number of highly-scalable

DEM simulations that can be performed on HECToR by

enabling simulation of laboratory tests routinely considered in geomechanics, for example. Specifically new boundary

conditions were implemented and the interaction model for two grains was

improved by, among others, implementing a new contact model for bonding between

two grains. On completion of this project it is now possible for DEM HPC users

to run stress-controlled simulations, or use an analogue to a membrane as part

of simulations of laboratory tests of granular materials. It is also possible

to simulate bonded granular materials such as porous rocks in HECToR, increasing the relevance of HPC to the DEM user

community. This document describes in detail the new features introduced to the

code and how these can be used to run test simulations of models much larger

than previously possible. An example of such a large-scale simulation is

included which demonstrates the potential of the use of DEM in an HPC

environment, producing results otherwise impossible to obtain.

Table

of contents

Abstract

Table of contents

Key objectives of

the work presented here

Implementation of

new boundary conditions for granular LAMMPS

Background

Modifications to

the FixWallGran class in LAMMPS

Use of moving and

stress-controlled rigid boundaries at the input script

Introduction of a

membrane boundary condition in LAMMPS

Background

Description of the

scheme chosen

Voro++, a software library for

carrying out three-dimensional computations of

Voronoi tessellations

Details of the implementation

of the new FixMembraneGran class

Testing of the

membrane code

Compilation of Voro++ on HECToR and inclusion of

the VORONOI package in LAMMPS

Use of the

membrane boundaries at the input script

Extension of the

contact models (pair styles) available in Granular LAMMPS

Background

Addition of the PairGranShmHistory class

The PairGranHookeHistoryPbond class that implements the new

bonding model

Verification of

the bonded interaction model

Use of the new

inter-grain interaction models at the input script

A large-scale

simulation that makes use of the new features implemented

Outcome of the

work and future prospects

Acknowledgements

References

Key objectives of the

work presented here

Typically

to date Discrete Element Method (DEM) simulations have been run on serial code

by the UK-based DEM user community. A previous EPSRC-funded research project (EP/G064180/1)

identified Granular LAMMPS as the most suitable open-source parallelised code

for large-scale DEM simulations. However, to enable full advantage to be taken

of the opportunities posed by using HPC facilities for DEM simulations it was

imperative for the boundary conditions implemented in Granular LAMMPS to be

developed. The first modification was to allow rigid wall movement, and so

allow for strain controlled simulations, i.e. simulations where boundary

displacement is specified. The second step was to implement a full

stress-controlled rigid boundary. This completed the first part of Work Package

1. With the second part of Work Package 1 membrane boundaries were implemented.

This allows the conduction of more realistic simulations of laboratory tests,

which are routinely confined by latex membranes. As this feature is not

currently available in any other open-source code, and requires a

computationally expensive Voronoi diagram calculation

it is thought that this inclusion will further increase the uptake of Granular

LAMMPS and High-Performance Computing by the DEM user community. It should be

finally noted that Dr Hanley (a co-member at the Imperial College LAMMPS

developer group) has already added another boundary condition, deforming

periodic boundaries for granular simulations to the Imperial College LAMMPS

code-base (Hanley, 2013).

Another

area in which LAMMPS required development was the inter-particle interaction

laws used for DEM simulations. A large amount of effort has gone into

developing these for Molecular Dynamics simulations. However the Granular

LAMMPS package which enables DEM simulations only contained a few basic models.

These included a linear and a non-linear elastic contact spring, with each

inter-particle interaction law implemented as a separate Pair

class. A new non-linear elastic contact spring model was created which was more

representative of a Hertz-Mindlin elastic contact

most appropriate for DEM simulations of frictional grains. However the main aim

of the second Work Package of this project was the addition of an interaction

law for bonded particles. This was done so as to allow the modelling of bonded

granular materials, such as porous rock or sandstone and so open up the use of

HPC to DEM users in the geological sciences. It further allowed for a larger

set of very interesting and potentially very important economically phenomena

to be investigated with Granular LAMMPS. Examples include the deformation of

sandstone after application of mechanical loads induced by drilling or

pore-fluid extraction with applications in the hydrocarbon industry.

Throughout

this document class names, variables and LAMMPS input commands are identified

by using a different font, e.g. compute_vector() so as to increase readability.

Implementation of new

boundary conditions for granular LAMMPS

Background

One

of the drivers for the development of DEM has been geotechnical engineering (Cundall, 2001, Cundall and Strack, 1979). The use of DEM has expanded since the

algorithm was first proposed (Cundall and Strack, 1979) and DEM has been adopted by a number of

scientific and engineering disciplines. However, the simulation of geotechnical

laboratory tests to develop a fundamental understanding of soil behaviour

continues to represent a significant proportion of DEM simulations that are

documented in scientific publications (e.g. Cui et al, 2007, Marketos and Bolton, 2010, Shen,

2012). Such simulations can provide key guidance as to how representative

material response can be best measured in the laboratory and have helped

analyse the effect of boundaries on force transmission and displacement

patterns inside a sample (which makes laboratory tests of granular materials

very difficult to interpret). At the start of the current project granular

LAMMPS only allowed the user to confine his sample with rigid walls, which

could only move sinusoidally or in a direction

coincident with the boundary plane (i.e. in shear). This functionality was

overly restrictive as in most DEM simulations users require more complex

control of the boundaries. This control is needed both in preparing the

granular samples for testing and during the main simulation procedure.

Modifications to the FixWallGran

class in LAMMPS

Flat

boundaries are implemented in LAMMPS in the FixWallGran class. The following additions were made to this

class for this project:

-

The

position (variables lo, hi) and

velocity (velwall) of the flat boundary was

included in the header file so that this be shared by all member functions.

-

Boundary

movement was implemented through function move_wall which at the first instance calculates the new wall

position through the formula

![]() (1)

(1)

It should be noted that a more

exact integration scheme might be implemented in the future should the need arise.

This was thought unnecessary at this point as granular LAMMPS also uses this

integration formula in the calculation of the shear force between two particles

(e.g. in PairGranHookeHistory::compute()).

-

The

total force applied by the walls to the particles was added as a variable in

the header file and was calculated for all particles owned by a specific

processor. An MPI_Allreduce command was then used to add

these and obtain the total force applied by the wall to the particles which was

stored in a 3-component array fwall_all .

-

The

function compute_vector() was added so as to allow access

to the wall positions and wall forces through the input script.

-

The

function velscontrol() was added. This sets the wall velocity so that a specific wall force

can be achieved. A proportional controller is used for this purpose and the

velocity of the wall at the next timestep is set

through the following formula

![]() (2)

(2)

where G is a gain parameter selected by the user through the input

script. Ftarget

is the target force at the current timestep (set by

the user through the input script) and Factual

is the actual force applied by the boundary to the particles interacting

with it. A more complicated controller could be implemented for this purpose

(e.g. Proportional-Integral or Proportional-Derivative) but this was

unnecessary for routine DEM simulations where the samples are stable and the

boundary force is relatively stable.

-

The

function modify_param was added so as to allow the

user to change the parameters or options for a flat boundary through a fix modify command.

Use of moving and

stress-controlled rigid boundaries at the input script

The

new flat boundary features can now be selected by the user through the fix wall/gran

command in a LAMMPS input script. The format of the input command remains the

same but optional arguments can be added to it to specify a moving or

stress-controlled rigid boundary. For a moving boundary the optional argument

is translate followed by three numerical values, that set the velocities in the x, y, and z

directions respectively. In order to stop wall movement the user can either set

the wall velocities to zero through a fix modify

command, or use a fix

modify command with arguments translate off.

The stress-controlled boundaries can be

specified through use of the optional argument stresscontrol followed by either a numerical value

or a character string starting with a v_ . In the first case the target force to be applied by the boundary to the

particles in a direction normal to the boundary is set to a constant. Note that

the sign convention used for force is the same as for the co-ordinate system

axes used, i.e. if a wall perpendicular to the x axis is used a positive value

will mean that the target force to be applied by the wall to the particles will

be in the positive x direction. Use of the character v_ instead of a number allows a time-varying target

force to be set through use of a LAMMPS style variable. It is thought that in most cases a user will want to perform a

simulation where the stress (i.e. the wall force divided by wall area) is

time-varying, and so the variable to be used for the target force

definition needs to include the positions of the points (or boundaries)

defining the edges of a wall segment. Some examples of commands that can be

used in the input script follow.

Rigid Wall Example 1

fix wallname

all wall/gran ${kn}

${kt} ${gamman} ${gammat} ${xmu} ${dampflag} zplane NULL 0.1 translate

0.0 0.0 -0.05

In this example a flat boundary (fix of

type wall/gran) with name wallname is created. The parameters enclosed in ${} are used to calculate the interaction forces between a boundary and the

contacting particles. The argument zplane indicates that the wall is

perpendicular to the z axis while the next two arguments specify the location

of the boundary in LAMMPS fashion. Thus, this wall is located at a z value of

0.1 and interacts with particles with z coordinates lower than that. As

discussed above the argument translate specifies that the wall will move by 0.05 length units / per time unit

in the negative z direction.

Rigid Wall Example 2

This example considers a

stress-controlled flat boundary with a time-varying target stress. This can be

specified through the following commands:

variable targetstress equal 1000.0*step*dt

variable targetFz

equal -${targetstress}*(f_yright[2]-f_yleft[1])*(f_xright[2]-f_xleft[1])

fix wallname

all wall/gran ${kn}

${kt} ${gamman} ${gammat} ${xmu} ${dampflag} zplane NULL 0.1 stresscontrol v_targetFz ${gain}

Here the first two variable commands specify the variables used

for the definition of the target force. For example if SI units are used for

the simulation the target stress for wall wallname is increasing with a stress rate of 1000 Pascals

per second. The target force for this wall is then set through the second

variable command, where f_yright[2], f_yleft[1], f_xright[2]

and f_xleft[1] are the coordinates of boundaries that

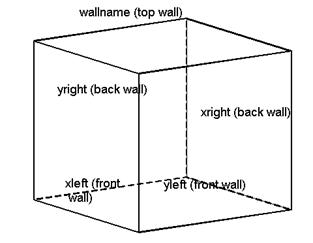

specify a three-dimensional simulation box, as defined by walls with names yright, yleft, xright and xleft (see Figure 1 below). The gain

parameter for the wall is specified by the last argument after the optional stresscontrol argument.

Commands similar to the above were used

to successfully stress a sample of approximately 1.45 million grains on HECToR (see p.19 below). This represents a milestone for

both the author and the research area as this simulation is significantly

larger than ones previously attempted.

Figure 1: A set of walls relevant for

the example input command given above.

Introduction of a

membrane boundary condition in LAMMPS

Background

In

many physical tests carried out in commercial and research soil mechanics

laboratories the samples are confined by membranes that can flex and deform as

the sample is compressed vertically. This extra degree-of-freedom in the

out-of-plane direction is not possible with the rigid-wall boundaries described

above, which overly constrain the displacement field inside a sample. For

example a number of very important experimentally observed phenomena (e.g.

shear banding) cannot be observed in simulations that use rigid boundaries,

leading to inaccurate predictions for the shear properties of granular

materials. To allow for the more accurate replication of laboratory test

conditions, it was necessary to implement an analogue to a membrane boundary

for use with Granular LAMMPS.

Simulations

of samples confined by membranes are not often performed as there is no

open-source or commercial code available that contains the numerical algorithms

required. Furthermore, the routines that implement this are computationally expensive

and so in order to run a representative three-dimensional simulation with a

sufficiently high number of grains the only solution can be running in an HPC

environment. For the above reasons the implementation of a membrane in Granular

LAMMPS was assessed as a high priority.

Description of the

scheme chosen

A

number of schemes have been proposed in the literature as analogues to a

membrane as summarised in Cheung and O’Sullivan (2008). They all rely on the

calculation of an equivalent weight or area for particles that are within a

distance from the edge of the sample, which is then used to calculate external

forces applied to the boundary particles - typically the force is the product

of this area and a specified pressure. A scheme that implements a numerical

membrane can therefore be separated conceptually in three main parts

A.

Selection of boundary particles

B.

Calculation of an equivalent area for each boundary particle

C.

Application of the membrane forces

Initially

membrane algorithms were developed for two-dimensional DEM simulations. In this

case the solution is less complicated than in the three-dimensional case as the

identification of boundary particles is straight-forward. Thomas and Bray

(1999) and Cheung and O’Sullivan (2008) used the lengths of the line segments

that connect the boundary particles in order to calculate membrane forces by

multiplying these by the membrane pressure value. Kuhn (1995), O’Sullivan

(2002) and Cheung and O’Sullivan (2008) all extended this concept to three-dimensional

simulations by projecting the outermost particle centroids onto planar or

cylindrical surfaces. The weight (or area) associated with each particle is

then found through the calculation of a two-dimensional Voronoi

graph for the points projected on the plane. The additional membrane force is

finally set to the membrane pressure value times the area for each boundary

particle.

Even

though the above represents some aspects of a membrane it has the disadvantage

of only applying membrane forces that are perpendicular to the projection

plane. A modified algorithm is proposed here so as to relax this condition. The

new membrane implementation is thought to be more applicable to cases where the

membrane flexes or bulges out of plane, and where the forces would deviate

significantly from a direction perpendicular to the membrane projection plane.

In

the scheme chosen for this work the starting point for both parts A and B is

the calculation of a weighted Voronoi graph (also

called Laguerre or radical Voronoi

graph – see Okabe et al, 2000) for the system of grains. The entire membrane

calculation is implemented as the self-contained class FixMembraneGran, itself derived from the LAMMPS Fix base

class. The forces on particles are incremented by the membrane forces through

the function post_force() which is

executed after the application of the inter-grain contact law for computation

of the force on particles due to the contact springs (i.e. after the Pair::compute()command).

A more detailed description of the implementation follows.

Voro++,

a software library for carrying out three-dimensional computations of Voronoi tessellations

The

implementation relies on the use of a Voronoi scheme

for the calculation of membrane forces. As in DEM simulations particles often have

different sizes (radii) the calculation of a Voronoi

graph weighted by radius is most appropriate. Such graphs have been used for

DEM before (e.g. Chareyre et al, 2012, Rycroft et al,

2009) but to the author’s knowledge it is the first time that these have been

used as part of a membrane calculation. It was therefore necessary to identify

a C++ library that included this calculation. Two possible candidates were

identified (CGAL and Voro++). Voro++

(http://math.lbl.gov/voro++/),

written and maintained by Dr Chris Rycroft of UC Berkeley was chosen as it

seemed easier to link into LAMMPS. Furthermore the Voro++

library carries out cell-based calculations, computing the Voronoi

cell for each particle individually and so fits in very well with the Granular

LAMMPS parallelisation scheme which relies on spatial partitioning of the

simulation volume.

At

the start of the project Voro++ was not linked to

LAMMPS. However, a discussion in the LAMMPS user forum initiated by the author

led to the release by the LAMMPS developers of a VORONOI

package, which contained extra code that computes a regular Voronoi

calculation for a group of particles (through the class ComputeVoronoiAtom). A new class (FixMembraneGran) was added by the author to this package to implement the membrane for

granular samples, and a new class to compute the weighted Voronoi

(or Laguerre) calculation for a group of grains (the new class ComputeLaguerreAtom). It should be noted that the VORONOI package can be optionally selected by

the user to form part of his/her LAMMPS build, if any of the Voronoi or membrane features are required.

Details of the

implementation of the new FixMembraneGran

class

As

a number of operations had to be performed on a weighted Voronoi

graph it was not possible to do the graph calculation elsewhere as part of a

LAMMPS compute class and then simply

communicate the areas required to the class implementing the membrane. Instead

all the calculations were included in a new LAMMPS class (FixMembraneGran). The new class contains a

number of member functions for initialisation, book-keeping and integration

with LAMMPS. The majority of the new code was added to member function post_force(), which gets called once every timestep. It should be noted that should future users wish

to speed up their simulations this function could be split into two parts, one

that updates the Voronoi graph used for the membrane

forces calculation, and one which calculates and adds the extra membrane

forces. The update of the membrane forces might then be called less frequently.

The function post_force()does the

following:

-

Initiates

two Voro++ container_poly

type classes which are used to perform the weighted Voronoi

calculations. The coordinates and radii of grains that belong to each processor

are then used as inputs to these container classes. The six edges for these

containers (required by Voro++ - see the Voro++

documentation) are set by the user through the input script. It should be noted

that the code might be made more efficient in the future by only adding grains

within a distance from the expected sample edges to these containers.

-

Loops

through the weighted Voronoi cells in the first Voronoi calculation. For each cell it loops through its set

of neighbour cells and checks whether a neighbour with a negative id exists.

Note that a negative neighbour id number in Voro++

identifies a cell that would extend to infinity. This step therefore identifies

the boundary particles for the sample.

-

For

each of the cells that extend to infinity it adds the coordinates of an

imaginary particle to the container used to calculate the second weighted Voronoi graph. This imaginary particle is added at a

distance twice the radius of the boundary particle in the direction towards

which infinity was detected. The effect of this is to condition the new

truncated boundary cell to pass through a point on the surface of the boundary

particle and to have a face parallel to the membrane surface.

-

Identifies

the faces between the particles in the simulation and the imaginary particles.

The areas (narea ) and their

contact normals are used for the force calculation.

-

The

force to be added to the boundary grains (Fextra) is calculated

as

![]() (3)

(3)

where pmembrane is the

membrane pressure. It should be noted that as narea is no longer

perpendicular to the membrane surface the extra membrane force on the particles

is no longer constrained in any specific direction. However the per-particle

membrane force is broadly perpendicular to the imaginary membrane surface. All

boundary areas are included in the calculation and at the force on a grain is incremented as the calculation progresses.

Testing of the membrane

code

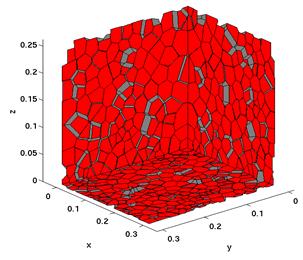

The

new membrane code was tested on the user’s local machine on a sample of 1600

grains confined by rigid walls on all six sides. After the sample was

equilibrated the rigid walls were replaced by membranes on all six sides, with

membrane pressures equal to the ones previously applied by the rigid walls. A

number of LAMMPS cycles were run and the sample was seen to maintain the stress

it was at. A plot of the Voronoi faces that make up

the surface of the membrane is shown in Figure 2. Faces with normals parallel to the membrane surface are plotted in

red. It can be observed that this new membrane algorithm successfully captures

the detail of the sample along its edges and follows accurately the boundary

surface of the sample. Simulations using this new membrane boundary condition

will now be run for comparison with simulations run with rigid walls. The

addition of this new boundary condition allows for the exciting prospect of

investigating the formation of shear bands and the observation of the failure

mechanism of a laboratory sample of sand, replicated with an

accuracy not previously possible in DEM simulations. As a consequence

the peak load a given granular sample can sustain will be more accurately

predicted too.

Figure 2: A plot of the membrane

faces for a granular sample of 1600 particles.

Compilation of Voro++ on HECToR and inclusion of

the VORONOI package in LAMMPS

Both

Voro++ and LAMMPS were compiled on HECToR using the GNU compiler. The following command needs

to be executed as a first step for both compilations

module swap PrgEnv-cray

PrgEnv-gnu

In

order to compile the Voro++ libraries (from the

source code obtained from http://math.lbl.gov/voro++/download/

) the following steps had to be performed

-

modification

of the config.mk file that comes with Voro++: CXX=CC

was set (instead of g++) and PREFIX=/home/e***/e***/username/vorodirectory (a directory where the user has write access)

-

execution

of the command make in the voro++

directory

-

followed

by make install

In

order to compile LAMMPS with the optional VORONOI package the following had to be

performed

-

the

file Makefile.lammps in folder src/VORONOI/

had to be modified by setting voronoi_SYSINC and voronoi_SYSPATH as follows

voronoi_SYSINC =

-I/home/e***/e***/username/vorodirectory/include/voro++

voronoi_SYSPATH =

-L/home/e***/e***/username/vorodirectory/lib

-

execution of the command make yes-voronoi in the LAMMPS src

directory to include the VORONOI package code in the LAMMPS

build. This should automatically update files Makefile.package.settings

and Makefile.package adding voronoi_SYSINC

and voronoi_SYSPATH. make yes-granular should also be executed for DEM

simulations.

-

execution of the command make NAME in

the LAMMPS src directory to make LAMMPS using the

settings in Makefile.NAME in the src/MAKE directory.

-

if a compilation error occurs

indicating that the Voro++ library cannot be found it

is most likely that the automatic update of the paths above has failed. The

user then needs to manually include the voronoi_SYSINC

and voronoi_SYSPATH lines in file Makefile.NAME used

above, plus the following command

voronoi_SYSLIB = -lvoro++

Use of the membrane

boundaries at the input script

The new membrane boundary can be selected through a

command of the following format.

fix membranename

all membrane/gran ${xleft} ${xright} ${yleft} ${yright} ${zbottom} ${ztop} ${pressurex} ${pressurey} ${pressurez} ${distx} ${disty} ${distz}

A membrane

boundary (fix of type membrane/gran) with name membranename is created. Parameters enclosed in ${} signify LAMMPS style variables that specified

through a variable equal command at the input script. Numerical values can also be specified for

these directly. Values for xleft, xright, yleft, yright, zbottom and ztop are the bottom and top limits in the x, y and z Cartesian axes

directions respectively for the container used in the calculation performed by

the Voro++ library. These should be set to be roughly

coincident to the locations of rigid walls that would form an imaginary

container bounding the whole assembly of grains in the sample.

Arguments pressurex, pressurey and pressurez are the membrane pressures for the faces perpendicular to the x, y and z

axes respectively. Here a positive value signifies an additional inward force

for the sample (i.e. compression is positive). If any of these arguments is

specified as NULL there are no extra membrane forces applied to the boundary

particles for that particular set of faces. This could be the case when a rigid

boundary is selected for this direction, for example. Arguments distx, disty and distz specify distance values necessary for correct calculation of membrane

forces when the code is run in parallel. They should be set to values lower

than the width of the minimum subdomain in the direction in question (x, y or

z) but should be larger than the expected distance of the centroid of a

boundary particle from the edges of the Voro++

container. When LAMMPS is executed in parallel a Voronoi

calculation is performed at every processor and inclusion of these parameters

ensures that membrane forces are only added for grains that are at the edges of

the sample, and not at inter-processor boundaries.

Extension of the

contact models (pair styles) available in Granular LAMMPS

Background

In

LAMMPS the inter-particle interaction is coded inside the Pair

classes. A large amount of effort has gone into developing these for Molecular

Dynamics simulations. However the Granular LAMMPS package which enables DEM

simulations only contained a few basic models. These included a linear and a

non-linear elastic contact spring, with each inter-particle interaction law

implemented as a separate Pair class. A new non-linear elastic

contact spring model was created which was more representative of a Hertz-Mindlin elastic contact most appropriate for DEM

simulations of frictional grains. However the main aim of the second Work

Package of this project was the addition of an interaction law for bonded

particles, making possible simulations of porous rocks and opening up the use

of HPC to DEM users in the geological sciences, among others.

Addition of the PairGranShmHistory

class

Dr

Kevin Hanley and Mr Xin Huang, members of the

Imperial College LAMMPS developer team identified that the non-linear elastic

interaction law in class PairGranHertzHistory

differed from the Hertz-Mindlin interaction (see Mindlin and Deresiewicz, 1953 or

Itasca, 2003) commonly used in DEM simulations. The calculation of normal force

(i.e. force in the direction of the vector connecting the centres of two

contacting particles) was that predicted by Hertzian

theory (Johnson, 1985) but the interaction in the plane perpendicular to that

(i.e. the shear or tangential interaction) differed. It was therefore thought

appropriate to add a new pair class (PairGranShmHistory) that implements a Hertz-Mindlin interaction. It should be noted that addition of a

new class instead of modification of the existing one was thought best for

backwards compatibility issues.

The

new class was implemented as a child of the PairGranHookeHistory class and so shares a number of

member functions necessary for Pair classes with it. The computation

of inter-particle forces (as redefined in the compute() function)

is very similar to the one for other granular classes, a key difference being

that the quantity stored in the per-particle shear[] array is now the shear

force from the previous timestep and not the

extension of the shear spring as in PairGranHookeHistory or PairGranHertzHistory . As mentioned above the normal

force in this new interaction model is identical to the one in PairGranHertzHistory::compute() for no contact damping. The shear

force equation implemented here however is the following:

![]() (4)

(4)

where ![]() is the

increment in the shear force at the current timestep,

G is the grain materials shear modulus,

v the Poisson ratio, δn

the displacement of the normal spring (i.e. the grain overlap), RA and RB the radii of the two contacting grains, Δt the timestep value and Δushear the rate of extension of the

tangential spring. It should be noted that no contact dashpot was implemented

in this Pair style as there are other LAMMPS fix

classes (e.g. FixViscous) that can be used to damp out

oscillations in DEM simulations. Also, to enable use of this new interaction

law in DEM simulations with flat boundaries the function shm_history() was added to the class that

implements the flat boundaries (FixWallGran).

The new pair class was then used for the simulations discussed on page 16, and

an example command will be given at the end of this section.

is the

increment in the shear force at the current timestep,

G is the grain materials shear modulus,

v the Poisson ratio, δn

the displacement of the normal spring (i.e. the grain overlap), RA and RB the radii of the two contacting grains, Δt the timestep value and Δushear the rate of extension of the

tangential spring. It should be noted that no contact dashpot was implemented

in this Pair style as there are other LAMMPS fix

classes (e.g. FixViscous) that can be used to damp out

oscillations in DEM simulations. Also, to enable use of this new interaction

law in DEM simulations with flat boundaries the function shm_history() was added to the class that

implements the flat boundaries (FixWallGran).

The new pair class was then used for the simulations discussed on page 16, and

an example command will be given at the end of this section.

The PairGranHookeHistoryPbond class that

implements the new bonding model

A

number of bonding models have been proposed for use with DEM simulations (Potyondy and Cundall, 2004, Utili and Nova, 2008, Weatherley,

2009). Of these the model proposed by Potyondy and Cundall is the one most often used. Members of the Imperial

College LAMMPS users group have used this model before in a number of simulations (Marketos and Bolton, 2009, Hanley et al, 2010, Cheung and

O’Sullivan, 2008) when using other serial codes and so it was thought that

addition of this model to Granular LAMMPS was most appropriate.

There

were two options for implementing the new bonding model in Granular LAMMPS.

This could be done through the use of either a bond style, or a pair style. The

bond style offered the advantage of a self-contained scheme for the calculation

of the interaction forces between bonded grains. However in LAMMPS such bond

styles are only available for Molecular Dynamics simulations. The challenge

when adopting LAMMPS bonds for Discrete Element simulations was that in DEM

extra per-bond memory needs to be allocated for the bond state information.

This memory then needs to be copied across processors when grains move through

processor boundaries and dealt with properly when bonds get added or removed

from a bond list.

Instead

the author chose to implement the bonded model as a Pair

class in LAMMPS. This offered the advantage of using the contact list (called a

neighbor list

in LAMMPS) to store the bond state information. The granular neighbor list logic is well-established in

LAMMPS and has been tested and debugged by numerous users over the past years.

It therefore provided a safe way of proceeding with the implementation of a

bonded model in the limited time available for this project. The following was

necessary as part of the new PairGranHookeHistoryPbond

class.

- The number of per-contact

quantities stored with the granular neighbor list

had to be increased. This was done through a modification to the FixShearHistory class so that it takes an extra

argument, the number of per-contact quantities to be allocated. The default

number of such quantities for granular pair styles in LAMMPS was 3, but the new

bonded model required 12 per contact quantities. Entries 0 to 2 of this per

contact array were reserved for the three Cartesian components of the extension

of the shear spring, similar to what was implemented in the PairGranHookeHistory class. Entry 3 was a number set

to 1.0 for bonded contacts or -1.0 for unbonded ones

and entry 4 contained the equilibrium distance for the bond normal springs,

used to calculate the bond force in the direction of the inter-grain contact

normal. Entries 5 to 7 were reserved for the Cartesian components of the shear

bond force and 9 to 11 for shear bond moment, while entry 8 contains the bond

moment in the direction of the inter-grain contact normal. Conversations with

Dr Christoph Kloss (JKU

Linz, Austria) when adding to the per-contact quantites

list were very useful.

- A compute() function

was coded. This implemented the equations as described in Potyondy

and Cundall (2004).

-

A

pbondflag was

introduced to indicate whether a bond exists at a specific contact.

-

Bond

creation was dealt with inside the compute() function.

A createflag was used to indicate whether

parallel bonds should be installed at all eligible contacts, typically at the

start of a simulation. The condition for bond installation was that the overlap

between two spheres should be larger than a specific value (d_install). If no d_install value was set by the user the

default behaviour was to install bonds at all contacts where there was overlap.

A negative value of d_install meant that bonds would be

installed to connect non-overlapping contacts while a positive value meant that

only contacts with overlaps greater than d_install would be bonded. Bond creation was only allowed in

the beginning of a simulation, or after the execution of a pair_modify

command.

-

Bond

breakage was checked for at every timestep. This was

done inside the compute()

function. The normal and shear bond stress were calculated and if these

exceeded a certain normal or shear stress the bond was set to break either in

tension, compression, shear or torsion. After bond breakage the inter-particle

interaction reverted to that of a contact spring alone.

Verification of the

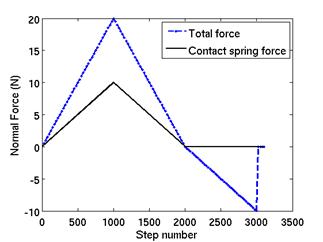

bonded interaction model

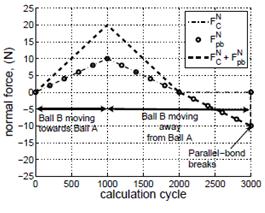

Cheung

(2010) detailed the results of an investigation of the behaviour of a two-grain

bonded system in commercial code PFC3D, which implements the model of Potyondy and Cundall (2004).

Two-grain simulations identical to the ones presented in Cheung were performed

here with a serial executable of LAMMPS in order to verify the implementation

for the bonded model. In these simulations two grains (A and B) of a radius of

0.5m were created just touching each other. The velocity and angular velocity

of grain A were set to zero and grain B was moved with both contact springs and

a parallel bond installed at the contact. A sketch of the 2-grain initial

positions is given in Figure 3. Figures 4, 5 and 6 plot the results for

simulations of inter-grain movement in the normal and shear directions and for

spin about the contact normal. The relevant figures from Cheung (2010) are also

shown for comparison. As the results agree very well the current implementation

of the inter-particle bonded interaction is verified.

Figure 3: A schematic of the

2-grain arrangement used for the bonding model verification simulations (after Cheung

2010)

(a) (b)

Figure

4: The results for inter-grain movement in the normal direction (creating

tension in the bond). Note that after 3000 steps the bond breaks. (a) LAMMPS and (b) Cheung (2010) results using PFC3D.

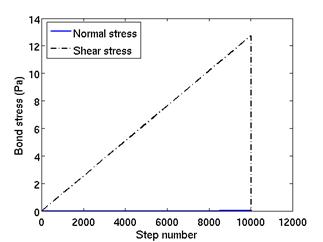

(a) (b)

Figure

5: The results for inter-grain movement in the shear direction. Note that after

10000 steps the bond breaks. (a) LAMMPS and (b) Cheung’s

(2010) results using PFC3D.

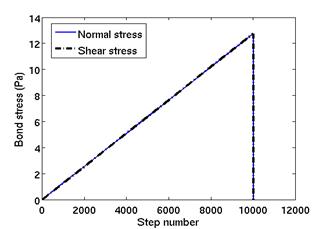

(a) (b)

Figure

6: The results for the case when one grain spins relative to the other. Note

that after 10000 steps the bond breaks. (a) LAMMPS and (b)

Cheung’s (2010) results using PFC3D.

Use of the new inter-grain

interaction models at the input script

The modified Hertzian

spring can be selected through the following command

pair_style gran/shm/history ${G}

${Poisson} ${mu}

Here the last

three arguments are the shear modulus, Poisson ratio and frictional coefficient

for grains respectively. These can be enclosed in ${} and specified as LAMMPS

style variables through a variable equal command preceding the pair_style command, or specified with their numerical values

directly. The above command needs to be followed by

pair_coeff * *

for compatibility with other LAMMPS pair

commands. In cases where a granular wall is needed with the new modified Hertzian model this should be specified through a command

of the type:

fix wallname

all wall/gran ${G} ${Poisson} 0.0

0.0 ${xmu} 0 zplane NULL 0.1

where the format of the wall command with

all its optional arguments is followed and the only wall parameters needed are

the shear modulus, the Poisson ratio and the frictional coefficient describing

the behaviour of the ball-wall contact.

The new bond

model can be specified through the command

pair_style gran/hooke/history/pbond ${kn} ${kt} ${xmu} ${kbn}

${kbt} ${nstrength} ${sstrength} ${bradmul} ${d_install}

where kn and

kt are the linear contact spring normal and

tangential stiffnesses and xmu

is the frictional coefficient for the contact. kbn and kbt are the spring

bond stiffness densities, nstrength and sstrength the normal and shear strength of the bond that

controls bond breakage. bradmul

is the ratio of the minimum radius of the two grain assembly that is used as a

radius for the bond disc and d_install is the overlap

above which bonds should be installed. Note that a negative value for this

means that bonds will be installed between non-contacting grains too. Again

this pair command needs to be followed by pair_coeff

* *.

A large-scale

simulation that makes use of the new features implemented

A

large-scale simulation was performed in an HPC environment so as to illustrate

the potential of the use of granular LAMMPS. 1.95 million grains were rained

under gravity and were equilibrated inside a container similar to the one shown

in Figure 1. The grain properties (e.g. grain size, density, stiffness) were representative

of a sample of fine glass beads used by experimentalists in Bristol University

in an ongoing EPSRC funded research project (EP/G064180/1),

and the sample container had the same dimensions as the laboratory container.

After raining of the particles the top was flattened by removing approximately

500,000 grains so that the sample used for the subsequent simulations contained

1,428,532 grains. The timestep chosen for this

simulation was chosen according to published guidelines (see Itasca, 2003) and

a stressing simulation was set up, with a stress rate of 200kPa/sec for all six

sides of the sample container, by using the commands described above.

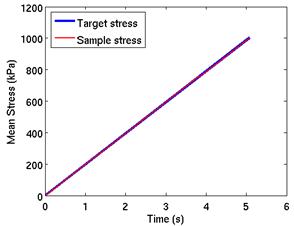

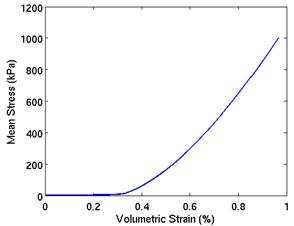

The

mean stress versus time and mean stress versus volumetric strain for the

simulation are given in Figures 7a and 7b below. In Figure 7a it is clear that

the sample stress indeed followed the target stress for the stress-controlled

moving wall. Figure 8 shows the results for a simulation where the gain

parameter was incorrectly chosen to be too low; here a system

instability can be observed as the wall stress oscillates above and below the

target stress. An appropriate value for the gain parameter for the

stress-controller was found by trial and error here; identification of this is

the topic of further work, but it should be a function of the sample stiffness

and stress rate. This is due to the fact that its value must depend on how fast

the target stress changes in a given timestep, and on

how much the boundary velocity affects the boundary force (i.e. what is the

value of the tangent to force-displacement curve for a boundary)

(a) (b)

Figure 7: Stress-controlled compression of a sample of 1.43million

grains (a) A plot of stress versus time (b) Mean stress versus volumetric strain.

Figure 8: Stress-controlled compression of a sample of 1.43million

grains: Sample instability for incorrect choice of the stress-controller gain

parameter.

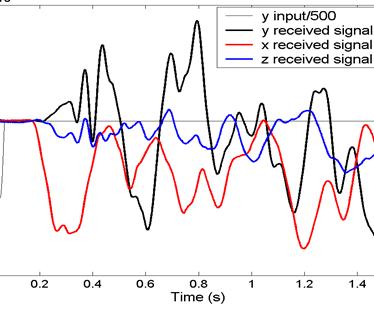

The

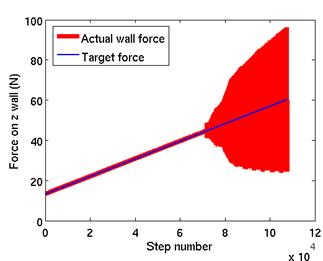

sample, which was stressed at 100kPa was then used for

a simulation of wave propagation from a point source, analogous to a bender

element laboratory test. This test is commonly used in the laboratory for

determination of the shear stiffness of a soil sample but the signals produced

are poorly understood. As part of the above-mentioned EPSRC-funded research

project (EP/G064180/1),

co-workers at Imperial have simulated a bender element test in smaller DEM

simulations (see O’Donovan et al, 2012). Simulations that have used HECToR have led to wave propagation virtual experiments in

larger samples (see Fig. 9 for a received signal for one such simulation). As briefly discussed above the use of HPC has allowed for the

direct replication of a laboratory test conducted by collaborators at Bristol

University on a material with much smaller grains. This is very

important as it has allowed for an increase in the number of full wavelengths

that can be contained within the sample and an increase in the wavelength to

mean grain size ratio, both of which affect profoundly the wave propagation

patterns observed. With this larger simulation it was therefore possible to

investigate more representative values for these parameters and identify their

exact effect of the signals received. Wave velocities, differences in the

shapes of the propagated signals and the exact wave propagation patterns within

the samples will all now be analysed with the aid of the data collected on the

larger samples.

Figure 9: The input and received

signals for a point-wave excitation simulation on a sample of 1.45million

grains that was stressed at 100kPa on HECToR.

Outcome of the work and

future prospects

The

simulation illustrated above represents a milestone for both the author and the

research area. It contains 30 times more particles than anything attempted

before by the author, while total simulation times, including

sample preparation were not in excess of six weeks. Sample preparation

was performed on cx1, the HPC cluster at Imperial College London, on 72 cores

using an infiniband inter-connect and took

approximately a month. The subsequent stressing was performed on HECToR using 8 fully populated nodes (256 cores) and took

approximately 48 cpu hours to reach a stress of 1MPa

representing a total simulation time of 5 seconds, i.e. a total of more than

20million timesteps. We have been monitoring the size

of simulations used in DEM simulations for geomechancis

applications (e.g. O’Sullivan, 2011) and we know of no other study where

analysts have simulated in excess of 1 million particles and compressed the

particle assembly in a controlled manner. This is therefore a significant

development for the research field.

At

the start of the author’s involvement granular LAMMPS we were not aware of any

UK academic running DEM simulations in an HPC environment. At the moment the

Imperial College DEM user group has four members, all of which are using HPC

for their DEM simulations and another member who is investigating the use of

granular LAMMPS and is considering adopting it over a commercial serial code he

is using. Simulations are currently being run on a number of very diverse

topics. These include simulations of wave propagation through sand, of

tunnelling through soil, of internal erosion through dam structures, of cyclic

loading of sand, and of liquefaction of sand. We are aware of the use of

granular LAMMPS on research projects directed by Dr Xia Li of Nottingham

University and Dr Jin Sun of Edinburgh University, both of which will benefit

from the developments resulting from the project described here.

The

author and co-workers are in the process of producing a publication in an

international refereed journal which will contain a description of simulations

conducted using the new features added to LAMMPS here. This will attract

attention to the use of HPC for DEM simulations and will act as a tangible

proof of the potential of the combined use of granular LAMMPS and HECToR for high-impact science. It is thought that this

will attract a number of new users to HECToR;

the author has already demonstrated the use of HECToR

to colleagues at Napier University for example. Furthermore, the developments

detailed here will allow more DEM users to move away from commercial codes and

free up EPSRC funds that were otherwise spent on software licences. It should

be finally noted that all developments detailed here are already part of the

Imperial College LAMMPS version that is shared between researchers locally. The

author has contacted Dr Steve Plimpton (the main LAMMPS developer) with the

intent of adding the new LAMMPS classes to the main distribution. Efforts are

also underway to add these to the LIGGGHTS

codebase (a software effort also based on granular LAMMPS) through

discussions with Dr Christoph Kloss,

one of its main developers. In the meantime the new features will be publicised

through replies to active discussion topics in the online LAMMPS user forum.

Acknowledgements:

This

project was funded under the HECToR Distributed

Computational Science and Engineering (CSE) Service operated by NAG Ltd. HECToR – A Research Councils UK High End Computing Service

- is the UK's national supercomputing service, managed by EPSRC on behalf of

the participating Research Councils. Its mission is to support capability

science and engineering in UK academia. The HECToR

supercomputers are managed by UoE HPCx

Ltd and the CSE Support Service is provided by NAG Ltd. http://www.hector.ac.uk

The

author would like to thank Dr Catherine O’Sullivan for her support and

encouragement throughout this project. Discussions on the implementation with

her and with Dr Kevin Hanley also of Imperial College London are gratefully

acknowledged. Dr Steve Plimpton and Dr Paul Crozier (Sandia National Labs), Dr Christoph Kloss (Johannes Kepler University, Linz) and Daniel Schwen

also deserve a mention for their invaluable discussions and help. The author

would also like to thank Dr Phil Ridley (Numerical Algorithms Group Ltd) for

his support.

References

Chareyre

B, Cortis A, Catalano E & Barthélemy E (2012). Pore-Scale Modeling of Viscous Flow and Induced Forces in Dense Sphere

Packings. Transport in Porous Media, Vol. 92,

No. 2, pp 473-493.

Cheung G &

O'Sullivan C (2008).

Effective simulation of flexible lateral boundaries in two-

and three-dimensional DEM simulations, Particuology,

Vol. 6, pp. 483-500.

Cheung, G. (2010). Micromechanics of sand production in oil wells. Ph.D. thesis, Imperial College London.

Cundall, P. (2001).A

discontinuous future for numerical modelling in geomechanics? Geotechnical Engineering

Proceedings of the Institution of Civil Engineers 149 (1), 41–47.

Cundall, P. and O. Strack (1979a).A discrete numerical model for granular assemblies.Geotechnique 29 (1), 47–65.

Cui L,

O’Sullivan C & O’Neill S (2007). An analysis of the triaxial apparatus using a mixed boundary three-dimensional

discrete element model. Geotechnique, Vol. 57,

No. 10, pp. 831-844.

Hanley (2013)

personal communication.

Hanley, K., O’Sullivan, C.,

Byrne, E. P. , Cronin, K. (2012) Discrete

element modelling of individual agglomerates of infant formula. Particuology,

10(5), pp 523-531.

Itasca

Consulting Group Inc. (2003).

PFC3D: Particle Flow Code in 3 Dimensions, Version 3.0, Minneapolis, USA.

Johnson, K. (1985). Contact

Mechanics. Cambridge University Press.

Kuhn MR (1995). A flexible boundary for three-dimensional DEM particle assemblies.

Engineering Computations, Vol,

12(2), pp. 175-183.

Marketos G & Bolton

MD (2009). Compaction bands simulated in Discrete Element Models, Journal of

Structural Geology, Vol. 31, pp. 479-490.

Marketos G & Bolton

MD (2010).

Flat boundaries and their effect on sand testing, International Journal for

Numerical and Analytical Methods in Geomechanics,

Vol. 34, pp. 821-837.

Mindlin RD & Deresiewicz H (1953). Elastic spheres in contact under varying oblique

forces. ASME Journal of Applied Mechanics Vol. 20, pp. 327-344.

O'Donovan J,

O'Sullivan C & Marketos G (2012). Two-dimensional discrete element

modelling of bender element tests on an idealised granular material. Granular

Matter, Vol. 14, pp. 733-747.

O’Sullivan, C (2002). The application of discrete element modelling to finite deformation

problems in geomechanics. Doctoral

Dissertation, University of California, Berkeley.

O’Sullivan C (2011). Particulate

Discrete Element Modelling: A Geomechanics

Perspective. Taylor and Francis, London.

Okabe A, Boots B, Sugihara K

& Chiu SN (2000) Spatial tessellations: concepts

and applications of Voronoi diagrams. 2nd Edition, Wiley.

Potyondy, DO and PA Cundall (2004).

A bonded-particle model for rock. International

Journal of Rock Mechanics and Mining Sciences, Vol. 41(8), pp. 1329-1364.

Rycroft CH (2009). Voro++: A three-dimensional Voronoi

cell library in C++, Chaos Vol.19, 041111

Shen C-K (2012) PhD Thesis, Imperial

College London

Thomas P & Bray J (1999). Capturing nonspherical shape of granular

media with disk clusters. Journal of Geotechnical and Geoenvironmental Engineering, Vol. 125(3), pp.169-178.

Utili, S. and R.

Nova (2008). DEM analysis of bonded granular geomaterials.

International Journal for Numerical and Analytical Methods in Geomechanics 32 (17), 1997–2031.

Weatherley, D. (2009). Esys-particle

v2.0 users guide. Technical report, Earth Systems Science

Computational Centre, University of Queensland.